First thing i did was go on google and look at off the shelf turbo kits for N/A cars like the integra and civic. I then realised theres not many parts to a turbo kit. Like in this photo

Going from around from left to right.

1. Turbo Dump pipe

2. External Waste Gate

3. Turbo Manifold

4. Turbo

5. Vacuum Hose

6. Intercooler and Piping

7. Silicone Hoses and Clamps

8. Blow off Valve

9. Oil Feed and Return Lines

10. Fuel Management (Not Pictured)

Looks simple enough? well i realised it isnt so simple after all after a hours of further research. Here are some problems i ran into during R&D

Turbo Manifold + Dump Pipe

The main problem when trying to turbo a FTO, the FTO being V6 has 3 exhaust outlets behind the radiator and another 3 infront of the firewall, having a look there it is a tight fit, and very hard to see how you would orientate the pipes to minimise turbulence, at the same time trying to fit everything in the engine bay. I had a talk with some exhaust shops around sydney, i was told they can make a turbo manifold with the front bank exhaust outlets for $800 and a dump pipe for $300, but only using the front 3 would slow down the spool of the turbo. I was then quoted $1500 for all 6 outlets. Now with that problem semi-solved it raised another question, where do i mount the turbo in the car?

here is a proposed turbo manifold and downpipe design...

Turbo + Wastegate Issues

Now i was told by several members on the forums, not run more than 6psi on standard internals and without lowering the compression. Im happy running 4psi daily but thats not where the problem arises.

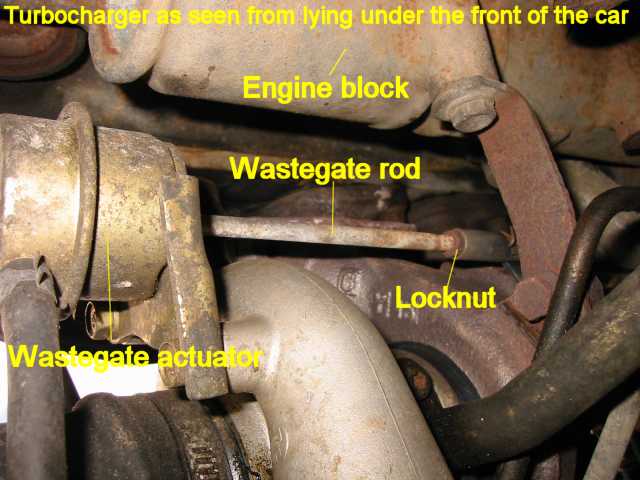

I had a look around for a few hours for a suitable turbo and realised most turbos off the shelf run at least 7psi, so i spent the next few hours researching how to lower this to 4psi, a manual boost controller wont work and then i asked RedlineGX how he got around this he told me a external waste gate.

Not being bothered with that, it almost destroyed my turbo dream, an hour or two later i then i stumbled upon a turbo saab or volvo site i cant remember, and they had a guide on how to decrease the boost on they turbo through the waste gate actuator rod. I quickly found out that loosening the rod (lengthen) will reduce the psi and screwing the rod in (shortening) will increase the boost. But not all internal waste gates are adjustable, the turbo i wanted (T25H) i quickly realised was not adjustable so now im after a T28, so if anyone sees any cheap ones around give me a pm!RedlineGX wrote:Basically you need to mount the wastegate on the upipe at any point between extractors and turbo. Either directly onto the pipe with a weld on flange or by running a custom pipe, maybe 1" or so to the wastegate from the upipe. This is what I did since it give a lot more flexibility in terms of wastegate placement.

The difference with external as opposed to internal is where the air goes. On an internal its automatically routed out the back of the turbo through the downpipe and out the exhaust. With an external the wategate blows to atmosphere which is a little better for performance but louder. You can either leave it that way or ad a small pipe to divert the hot air out of the engine bay under the car etc and reduce a little of the noise. Or you can run a longer pipe and plumb it back into the exhaust at any point before the O2 sensor which would be quieter but require more work.

Also if you get a turbo with an internal wastegate and you need to run an external one you might have to weld shut the valve so it doesnt open anymore depending on the spring rate.

Turbo Issues Part 2

Ok, the t28 i am after is water cooled and oil cooled, RedlineGX has a fairly easy solution to feed the turbo with oil. The water cooling part is what im worried about, where do i get the water to cool the turbo?

after reading hobbsie's post ive realised theres a little hose that goes into the throttle body with coolant, is it ok to tee this and take some coolant going there to cool the turbo? or is there a better place? or can i just cool it on oil alone?

this is what im planning to tee it with at the throttle body

now for coolant do i use a vacuum hose or a fuel line hose?

Blow off Valve

This was fairly straight forward, but not wanting to weld, i looked for a solution to see if you can have a non-welded blow off valve.

I can up with this

flange for greddy blow off valve

to go into a silicone tee hose like this

problem solved, so at any time i get done for having a blow off valve, i can quickly remove it and replace with a straight silicone hose.

Fuel Management

Said to be one of the most expensive aspects of a turbo kit, i had a look online to find that, most kits under 7psi dont come with a safc or new ecu or even a piggyback. Realised heaps of americans are running what they call FMUs (Fuel Management Units)

here is a a quote from another forum

thermal wrote:As we all know, the intake manifold on a non-force induced engine is always on a vacuum state. Once the engine is subjected to Force Induction by either a Turbo or Supercharger, the intake manifold will become a pressurized component. A pressurized intake manifold dictates more volume of air for combustion purposes. However, the added volume of air will not burn properly unless ample fuel is provided. The Vortech FMU is a “rising rateâ€